How to process the IMD phone case?

With the widespread use of mobile phones around the world, the mobile phone case market continues to grow.At the same time, there are more and more different types of mobile phone cases on the market.As the current popular IMD(In-Mold Decoration) mobile phone case, it can be customized, the pattern is real and clear and will never fade, can achieve difficult design effect, has been deeply welcomed by the major international mobile phone case brand owners and wholesalers.

Now I would like to introduce to you the specific production process of IMD technology:

1. IMD cutting material:

Cut the rolled Film into square blocks of designed size to prepare for the printing process.

1.1imd cutting material 1

1.2imd cutting material

2. Pre-shrinkage:

Before printing, the cut Film is heated in the oven to minimize the chance of shrinkage.

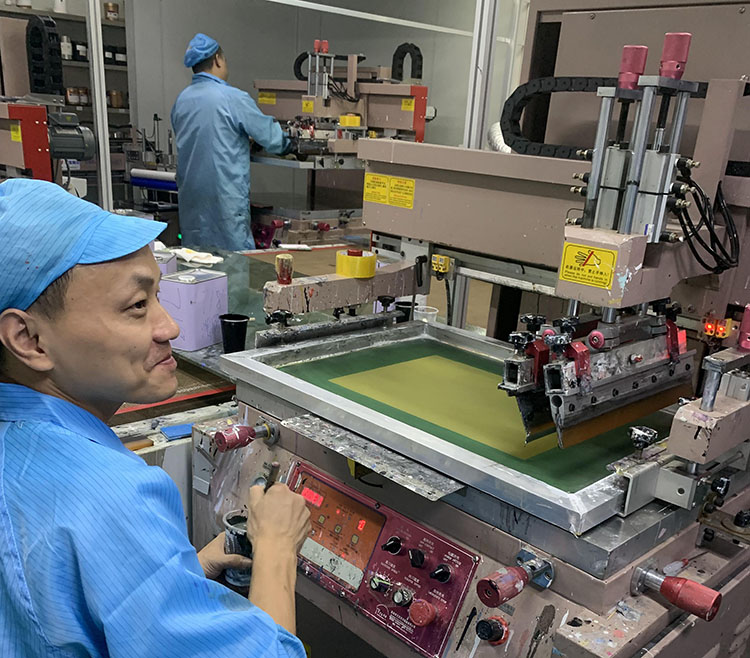

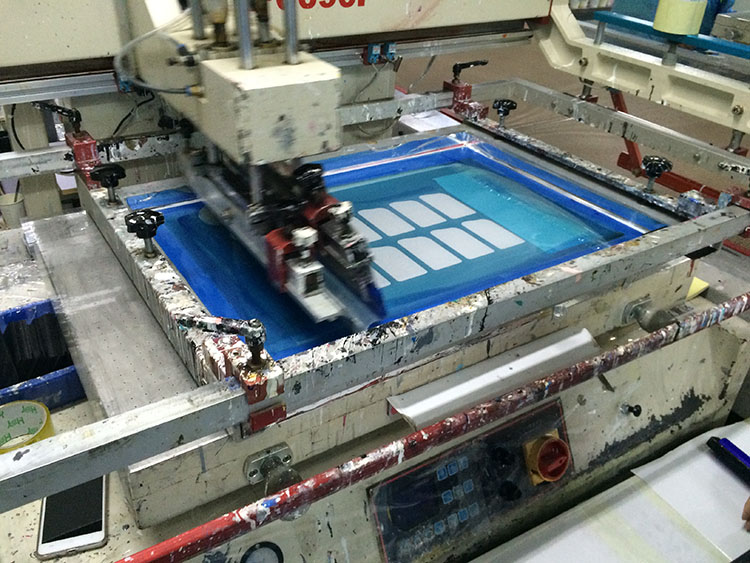

3. IMD graphic printing:

According to the custom-made mobile phone shell design street patterns, text manufacturing into Film net, in the cut Film square block printing patterns and text.

3.2 imd silk screen printing

3.3 imd silk screen printing

3.4 imd silk screen printing

4. IMD ink drying and fixing

The printed Film square block is placed in the high temperature oven to dry, the purpose is to completely solidify IMD ink, the solvent in the ink evaporation.

4.1imd ink drying and fixing

4.2imd ink drying and fixing

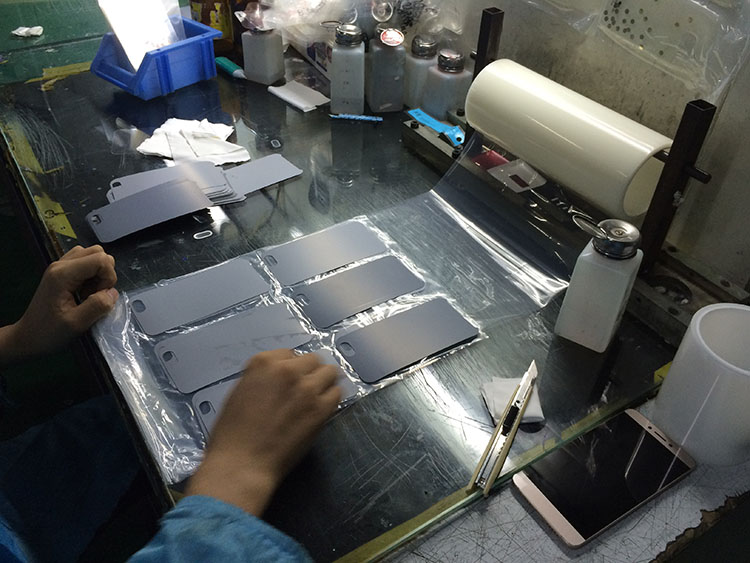

5. IMD paste protective Film:

Avoid the printing of the Film surface during the positioning hole process, sometimes need to paste a single or double protective Film.

6. IMD punching positioning hole:

The positioning hole in the shearing process and the hot forming process must be punched accurately.

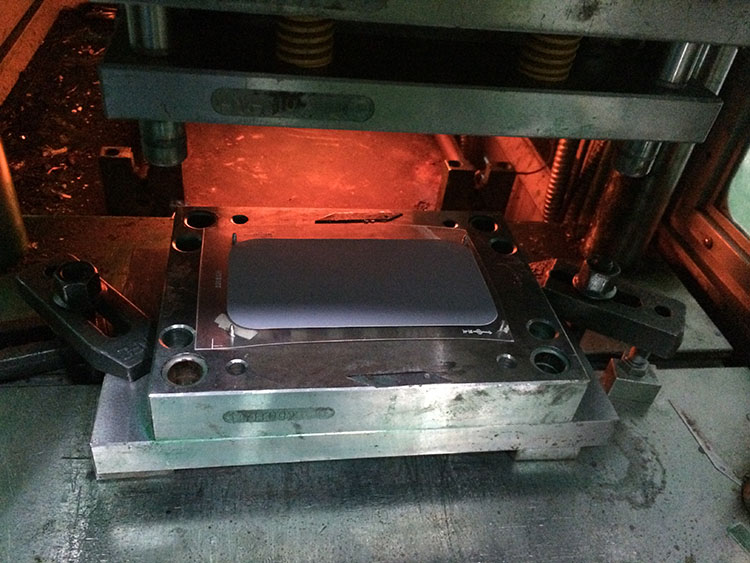

7. IMD thermal molding (high pressure or copper mold) :

After the printed film is heated, it is formed under preheating state by high pressure machine or copper mold.Forming Mold design is critical.

8. IMD shear peripheral shape:

Cut off the waste of the formed three-dimensional film.Precise shear mode is required.

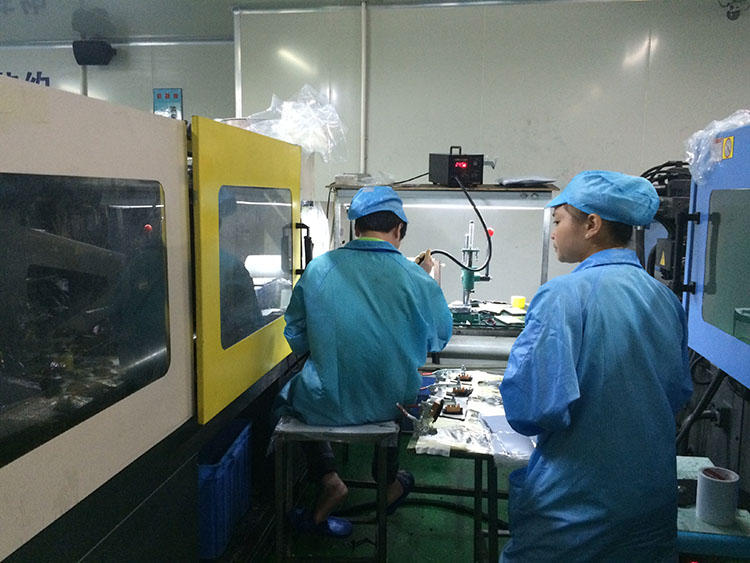

9. IMD injection molding:

Place the film with the same three-dimensional shape on the front mold after molding to inject the finished IMD product

9.2 imd injection molding

9.2 imd phone case injection

9.1 imd injection molding

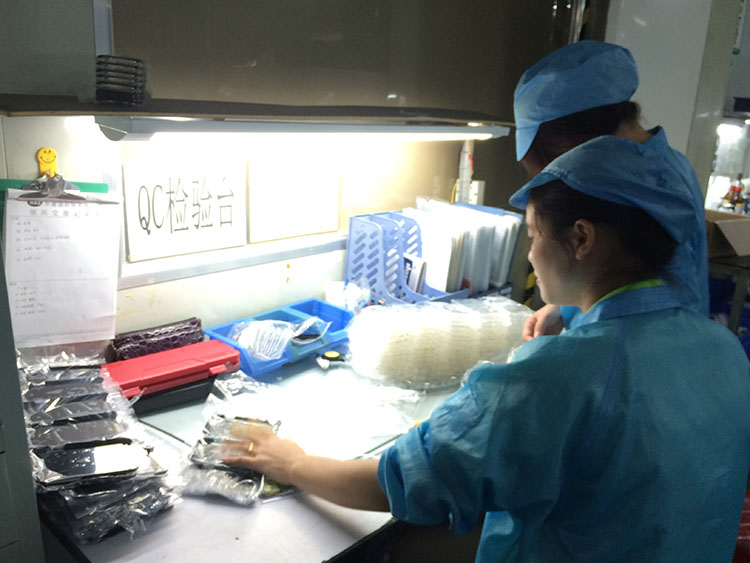

10. IMD testing:

Transfer the completed IMD mobile phone case to the inspection workshop for product testing and shipment.

10.1 imd testing

10.2 imd testing

10.3 imd testing

Go through the 10 processes above.IMD technology popular mobile phone case through cutting, printing, injection molding and other processes into the market popular IMD mobile phone case.These production processes are only necessary in our production process.But in the production process also needs a lot of detail work preparation and unexpected exception handling.Through this article IMD mobile phone shell manufacturing process to share, I believe that we have a general understanding of IMD mobile phone shell.If you need to order and customize IMD mobile phone case, please contact us!

Meanwhile, our company has own mold workshop and can open mold for customers to customize the mobile phone case. We can also use our company’s public mold for the production of customers.It all depends on the customer’s own requirements.