New IMD Coated Phone Case

Accept OEM custom and stock order

- Any Logo and Design

- Lots of Custom Options

- Eco-Friendly Material

- Shockproof & Anti-yellow

- Clear Chic Floral Patterns

- Lightweight & Scratch-proof

Additional information

| Material | TPU |

|---|---|

| Effect | Injection |

| Phone | iPhone Series |

| Color | Optional |

| MOQ | 50pcs |

Product Details

iPhone13 series phone case for your reference.

、

Case Material: High-Quality Bayer Plastic Material

Colors: Multiple, custom available and depending on requirements

Print Methods: Silk Screen Print, UV Digital Print, 3D Sublimation, Electroplating

Molding: According to requirement make the mold or factory opening mold.

Packing: Make packaging as required by customers or factory-neutral packing.

Delivery: Stock Case is sent in advance or custom by the client by Express(DHL, FedEx, UPS) or Air, Sea.

LuckNine has always focused on phone case design and molding for more than 10years.

Leave you message or contact us directly to obtain more useful support for your business.

IMD Sublimation Mobile Phone case for Custom Step

The Custom Phone case Step is as follow:

1. Send your design to us. Our designer and engineer will check our design and release.

2. According to the client’s requirement to release the samples and show the phone case design effect to check with the client.

3. After confirming the design we will injection the phone case and check with the client needs to send it to check or not.

4. Inspection package workshop will double-check the phone case quality and order quantity.

5. Quality controller will check all phone case quality and then arrange the delivery.

Printing PET film

Printing different designs and patterns from client drawing to release HD effects. The main point is the color modulation and color match.

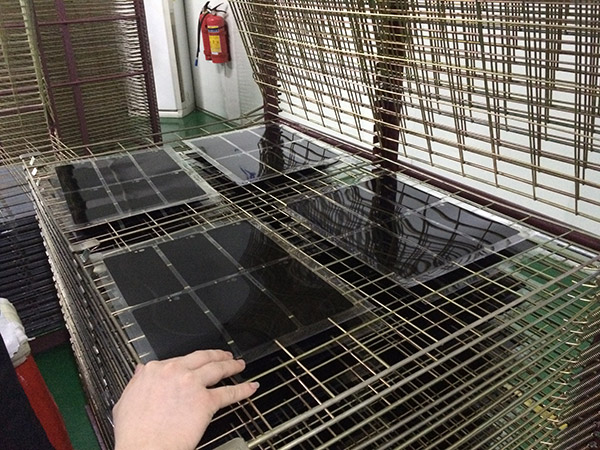

Forming the PET film

After drying the PET film ink. We need to forming the whole PET film to a phone case shape.

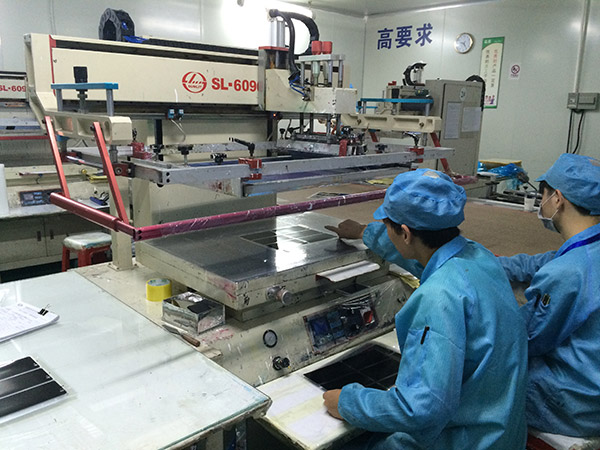

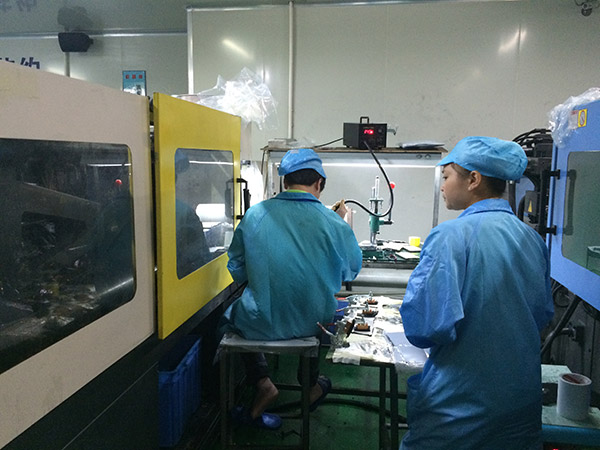

Injection phone case

When we forming the phone case to one by one. And then transfer to the injection department to molding the phone case. This step is very important. The quality controller will pay more attention to follow this inection process.

Inspection phone case

From printing, forming and injection. The phone case has released. Although each process we have inspector and quality controller to control the quality. we also need the inspection step to check the phone case quality one by one in order to make sure all case is the good quality to reach our client hand.

Factory Tour

50 injection machine

300 experiencd staff

Strict QC system